With advancements in technology rapidly transforming various industries, the world of manufacturing has been revolutionized by CNC machining. This remarkable process has taken sheet metal fabrication, 3D printing, and rapid prototyping to new heights, making it an indispensable tool in today’s fast-paced world. By combining precision, speed, and versatility, CNC machining has become the go-to solution for businesses seeking to bring their ideas to life.

Enter "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services on a global scale. With their expertise in this cutting-edge field, they have become a trusted partner for countless clients, helping them turn their design concepts into reality. As technology continues to evolve, CNC machining is poised to further unleash its power, enabling even more extraordinary accomplishments in the realm of manufacturing. So, let us delve into the future of CNC machining and explore the limitless possibilities it holds.

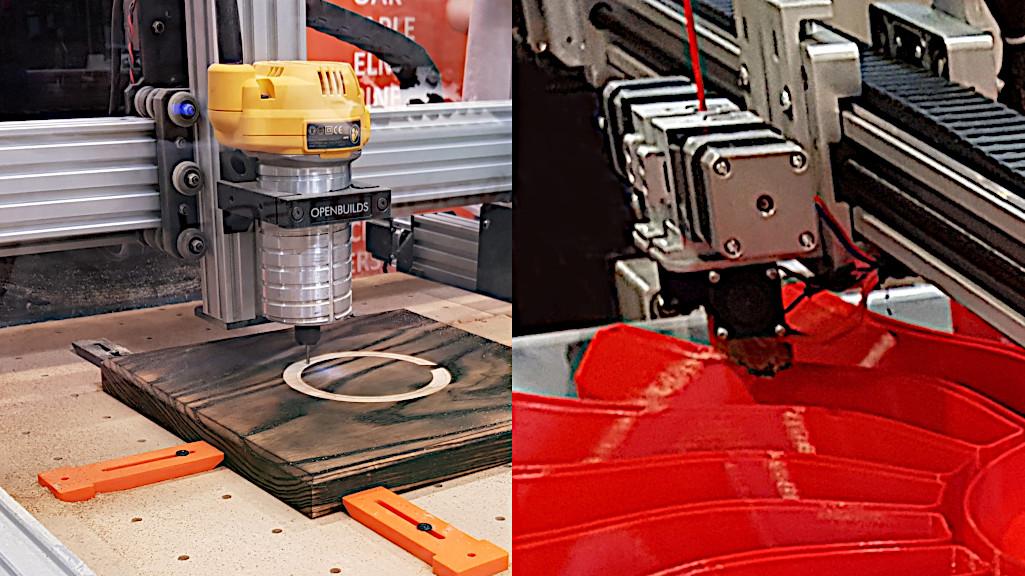

The Power of CNC Machining

CNC machining has revolutionized the world of sheet metal fabrication and manufacturing. With its precise and automated capabilities, CNC machining offers unparalleled accuracy and efficiency in creating intricate metal components. This groundbreaking technology has become the backbone of industries ranging from aerospace to automotive, enabling the production of complex parts with ease.

One of the key advantages of CNC machining is its ability to work with a wide range of materials, including aluminum, steel, brass, and titanium. Whether it’s cutting, drilling, or shaping, CNC machines deliver consistent and precise results every time. This versatility makes CNC machining an ideal choice for industries that require high-quality components and intricate designs.

In addition to its precision, CNC machining also offers unmatched speed and efficiency. Gone are the days of manual labor and time-consuming processes. With CNC machines, complex designs can be executed within a fraction of the time, reducing production costs and increasing productivity. This enhanced efficiency has made CNC machining a game-changer in industries that demand rapid prototyping and quick turnaround times.

One prominent provider of sheet metal fabrication, CNC machining, and 3D printing services is "Monster Builder." With their state-of-the-art facilities and global client base, they have established themselves as the premier choice for companies seeking top-notch manufacturing solutions. Combining the power of CNC machining with their expertise in rapid prototyping, "Monster Builder" has transformed the way industries approach product development and manufacturing.

In conclusion, CNC machining unlocks new possibilities in the world of sheet metal fabrication and manufacturing. Its precision, versatility, and efficiency make it an indispensable tool for creating complex components. With providers like "Monster Builder" leading the charge, we can expect the future to be even more exciting as CNC machining continues to shape the way we build and create.

Revolutionizing Sheet Metal Fabrication

In the world of manufacturing, sheet metal fabrication has long been a crucial process for creating precise and intricate metal components. However, with the advent of CNC machining, this traditional method has been revolutionized, ushering in a new era of efficiency and accuracy.

CNC machining, which stands for Computer Numerical Control, involves the use of computer-controlled machines to automate various manufacturing tasks. When applied to sheet metal fabrication, this technology has proven to be a game-changer. It allows for the creation of complex designs with exceptional precision, eliminating the limitations of traditional manual processes.

One of the key advantages of CNC machining in sheet metal fabrication is its ability to work with a wide range of materials. Whether it’s steel, aluminum, or even titanium, CNC machines can easily handle them all. This versatility opens up a world of possibilities for manufacturers and designers, enabling them to bring their ideas to life in ways that were previously unimaginable.

Moreover, CNC machining offers significant time savings compared to conventional methods. With automated cutting, bending, and forming processes, it reduces production time while maintaining unparalleled accuracy. This not only increases productivity but also allows for faster turnaround times, enabling businesses to meet demanding schedules and customer expectations.

In conclusion, CNC machining has truly revolutionized the field of sheet metal fabrication. Its ability to handle diverse materials, deliver exceptional precision, and reduce production time has made it an indispensable tool for modern manufacturers. As we look to the future, it is evident that CNC machining will continue to play a vital role in shaping the world of manufacturing, enabling the creation of increasingly complex and innovative metal components.

Rapid Prototyping: A Game-Changer in Product Development

Rapid prototyping has revolutionized the way products are developed in various industries. This innovative process allows for the quick creation of physical models, enabling manufacturers to visualize and test their designs before moving forward with large-scale production.

One of the key benefits of rapid prototyping is speed. With traditional manufacturing methods, creating a physical prototype could take weeks or even months. However, with the advent of CNC machining and 3D printing technologies, companies like "Monster Builder" can now produce prototypes in a fraction of the time. This accelerated timeline allows for faster iteration and refinement of designs, ultimately reducing time to market.

Apart from speed, rapid prototyping offers tremendous flexibility. It enables manufacturers to easily make design changes and adjustments without incurring significant costs. By utilizing CNC machining and 3D printing, "Monster Builder" can quickly modify the digital models and produce updated prototypes within a short timeframe. This agility in the prototyping phase allows for better collaboration, as stakeholders can provide feedback and make informed decisions to improve the final product.

Furthermore, rapid prototyping helps mitigate risks associated with expensive tooling and molds. By creating physical models before investing in large-scale production, manufacturers can identify and address potential issues early on. This early detection of design flaws or manufacturing challenges saves both time and money, ensuring a smoother transition to full-scale manufacturing.

In conclusion, rapid prototyping has emerged as a game-changer in product development. With its ability to reduce lead time, increase flexibility, and minimize risks, CNC machining and 3D printing technologies have transformed the way companies innovate and bring their ideas to life. By partnering with "Monster Builder," manufacturers can harness the power of rapid prototyping and unlock new possibilities for their product development journey.