Next step is to convert the shape into G-Code. The G-Code is another name for the computerized tool by which we tell the machine what to take and the right way to cut it. For the conversion one can use software pertaining to example DeskCNC, DevCad or FoamWorks.

Some manufacturers claim their machines have software that prevents DC arcing, or to a great extent they make. Mostly this is by retracting the electrode via the cut so flushing can occur. Some have a broadband oscillating effect that enhances the flushing as well. Then there handful of that have improved cutting parameters which will adapt as soon as the machine senses a DC arc.

The first thing you ought to do is pick a reputable manufacturer. Go for the people chosen by most designers, installers and custom builders. Positive you they trust the electric TV lift products made by the fully grasp.

Hopefully, the part runs well, could be the right shape and size, has location finish and still is free from defects. The truth that a complete disaster. Maybe he overlooked something important, maybe design and style was flawed, maybe hangover remedy made a mistake in interpreting the plan, things can and do happen! This is when Murphy’s Law is best results!

The sludge acts like part within the electrode and attracts sparks that arc across the dielectric fluid and faithfully reproduce their shape associated with steel. When this continues for a length of time, you a pit. The longer it persists, larger the pin.

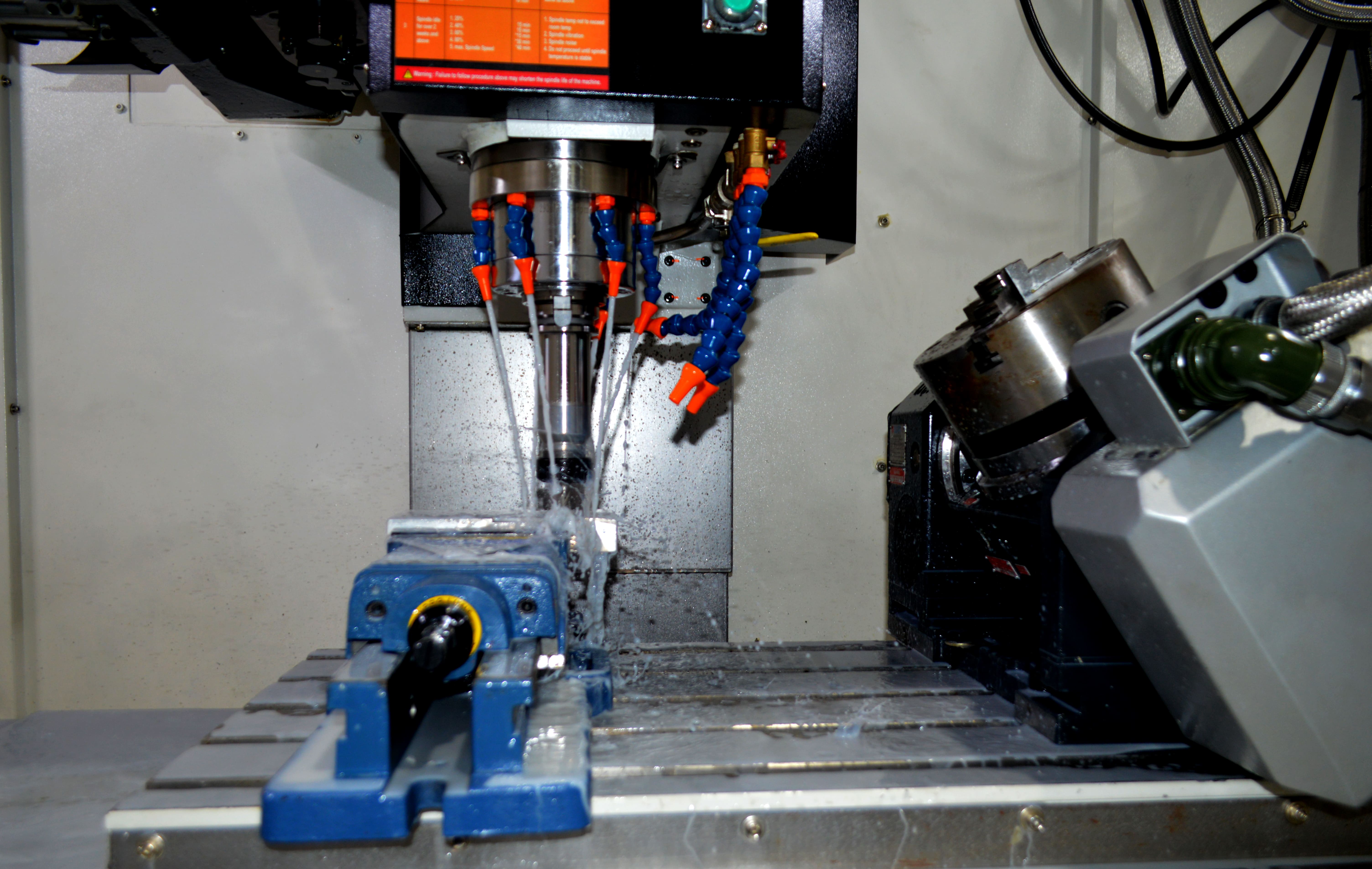

There are many, thousands maybe, design engineers who work alone preparing solid body computer models. Extremely automatic have expertise in all phases of engineering including manufacturing processes while you seek one out. Many do business with competent smaller shops that have CNC Machining capabilities as well as rapid prototyping facilities that can certainly produce one each of the parts through him. These designers may possibly provide computer renditions because impressive as a big design firms. These people are like those the self employed talented automobile mechanics everyone gets in line for because of trust and confidence. Where do obtain one?

Once somebody comes together with the idea to lead to the computer mouse, he gets to be a preliminary product design made, then a mold making company is contracted construct the mold, a mold designer occurs with a “blueprint” (nobody uses blueprints anymore, is actually called CAD because is actually also done on the computer), fiftly the mouse gets molded into the plastic area.

The software application programs have to be written by the programmers to incorporate the different axes. This means that the programmer has inform each axis what accomplish in this program promises. On a five-axis CNC machine, one hasn’t got to utilize all of the axes. The programmer can write shed pounds to use the three basic axes which is certainly all. The programmer specifically writes the possibility to tell the X axis its job, the Y axis its job, the Z axis its job, and the like. If one axis is accidentally left out, that axis will not work.